If you are working with metal, you are probably well aware of how resourceful a smooth metal cutter can be. Metal cutters are machines that can shear sheet metal and plates. These tools can be found in many metal factories, workshops, as well as residential homes where they are used for the occasional metal roofing or other odd jobs. There are many different metal cutters ranging from table shears to swivel shears. Swivel shears in particular, are the sigh of relief for people who frequently have to cut through sheet metal.

Corded or Cordless?

Corded options like a table shear now seem rather ancient in the era where we are pushing the boundaries of technological innovations. Not only is a cordless electric metal cutter very convenient for moving around, but it also fits ergonomically in your hand. Many modern designs help keep your wrist in proper alignment with the tool, which can prevent soreness.

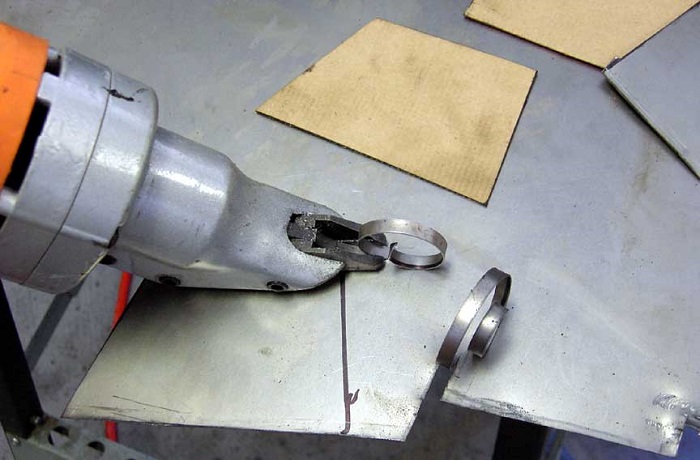

Cordless shears are the number 1 requested tool for cutting metal by professionals and amateur users as well. They usually include a number of features that make working with metal faster and more efficient. For instance, an electric metal cutter that has a 360 degree swivel feature allows the user to easily work in any position and every angle. Another helpful feature to look for is an all-ball bearing motor which can allow for non-stop use for prolonged periods of time without overworking the tool.

The Right Shear Gauge for the Job

What shear gauge you should use depends entirely on the type of metal you are cutting. For low carbon steel which is a softer material (if there’s such a thing as soft with metal), using a maximum 18 gauge will ensure you make clean and safe cuts. If you’re dealing with stainless steel which is harder to cut through, amping up the tool to a 20 gauge can allow you to slice metal like it’s bread.

To increase the efficiency of your cutting, you can adjust the speed according to the metal width and the types of cuts you are making. An impact-compatible shear attachment is perhaps the most versatile additional feature an electric metal cutter can have. It can easily knuckle down hard materials such as corrugated or sheet metal, asphalt shingles and steel mash, as well as materials like rubber, wire, plastic and much more.

Features that Guarantee a Smooth Finish

Normally, when you cut metal you expect to receive a smooth and clean finish to the material. This can be accomplished if the metal cutter keeps the blades in proper alignment as they pass each other. Models of swivel shears that have either a slider unit or a swing beam design can guarantee that the cut material ends up with a sleek look. The slider unit has a drive system which turns the blade down and in a position which is parallel to the blade that is fixed. In comparison, the swing beam shear has a drive system that rotates the moving blade down on the roller bearings and in optimal position.