LATEST ARTICLES

Unlock Your Potential: The Ultimate Guide to Bodybuilding Supplements

Sole to Board: Why Nike SB Shoes Are Essential for Skaters

Woof Control: Steps to Choosing the Right Bark Collar for Your Dog

Striking Performance: Steps to Choosing Adequate Cricket Shoes

6 Steps to Take Towards an Eco-Friendly Life

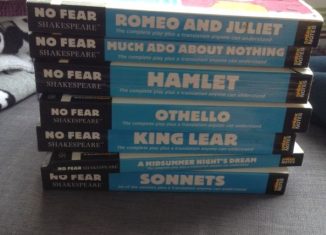

No Fear Shakespeare: Step Up Your Child’s Knowledge on Classic Literature

Scent Harmony: Steps to Choosing the Ideal Perfume for You

Photo Prints: The Ultimate Home Decor Statement Piece

Yeezy Boost 350: The Right Step to Elevate Your Wardrobe