Even though wireless devices are becoming increasingly more popular, wires are still essential pieces of equipment in every household and commercial buildings. By simple definition, a wire is any metal (typically copper) that’s been shaped or drawn that’s considerably longer than its cross section. Most commonly, wires have cylindrical or round cross-section, even though there are use for more specialised applications that require square or flat cross sections.

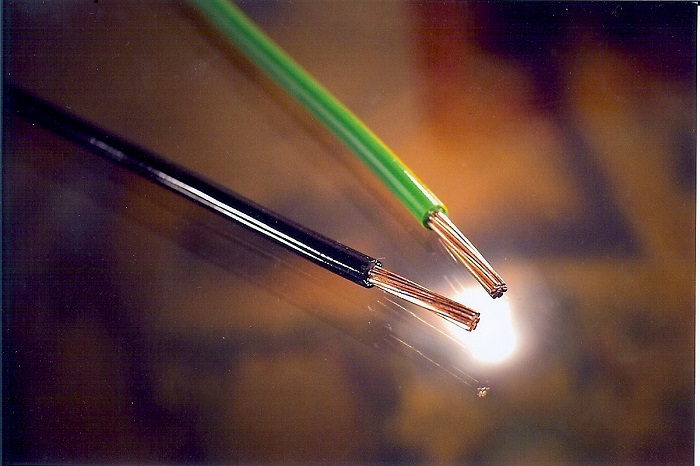

Choosing the right wire for a specific application is impossible without some basic understanding of its characteristics, the termination and its load-carrying capacities. For most electrical applications, a single conductor wire should be sufficient enough as long as it’s insulated. The insulation is typically a pliable, soft plastic added to the wire after forming. This is accomplished through an extrusion process, where the conductor goes through the extrusion die, together with the melted plastic that’s formed around it.

For most modern applications, wires are covered by an extra layer of insulation, called a jacket. These bundles are called cables. A single core cable typically has same diameter wires that are twisted together, but there are also cables manufactured that contain different size wires, where the wires are insulated in different colours for easier identification. A single core cable can be used in both low and high temperature areas, including aviation, ship building industries, glass, steel and cement producing industries as well as ceramic factories. They can be halogen-free, which makes them ideal for use in power stations.

When buying a cable, the way in which it’s going to be used and the amount of current it can carry must be considered. There are four important factors to keep in mind:

- number of conductors,

- flexibility,

- amperage, and

- connection.

For more specialised cases, there are extra factors to consider, like abrasion resistance and temperature, however, they’re not the norm.

You can easily find any type of cable you need online, you just need to know what you’re looking for. Reputable manufacturers generally provide a full specification sheet so that you know exactly what you’re getting. If you’re looking for a specific type of cable, you should input as much information as possible into your search. Alternatively, most reputable and quality cable manufacturers or suppliers will answer all your questions once you contact them and tell them what you require. Informing yourself before purchasing is key, as there is a wide array of cables available, so picking the right one can be a bit challenging.